Miniaturized Medical Device Expertise

We offer our customers comprehensive expertise in electronic miniaturization for innovative medical devices. The trend in the medical industry is for smaller, handheld, portable and implantable devices. Handheld, cordless, lighter devices help physicians and surgeons perform their examinations and surgical act with more comfort and accuracy. Smaller endoscopy devices allow for less invasive procedural techniques and, therefore, less trauma during surgeries and other minor procedures. Small-scale, connected, and user-friendly equipment allow to treat patients from home, improving their quality of life. Innovative tiny active implants allow for huge progress in challenging health issues such as diabetes management, deep brain stimulation and relief of chronic pain.

Trend for smaller devices

Equipment size reduction

Extremely miniaturized implants

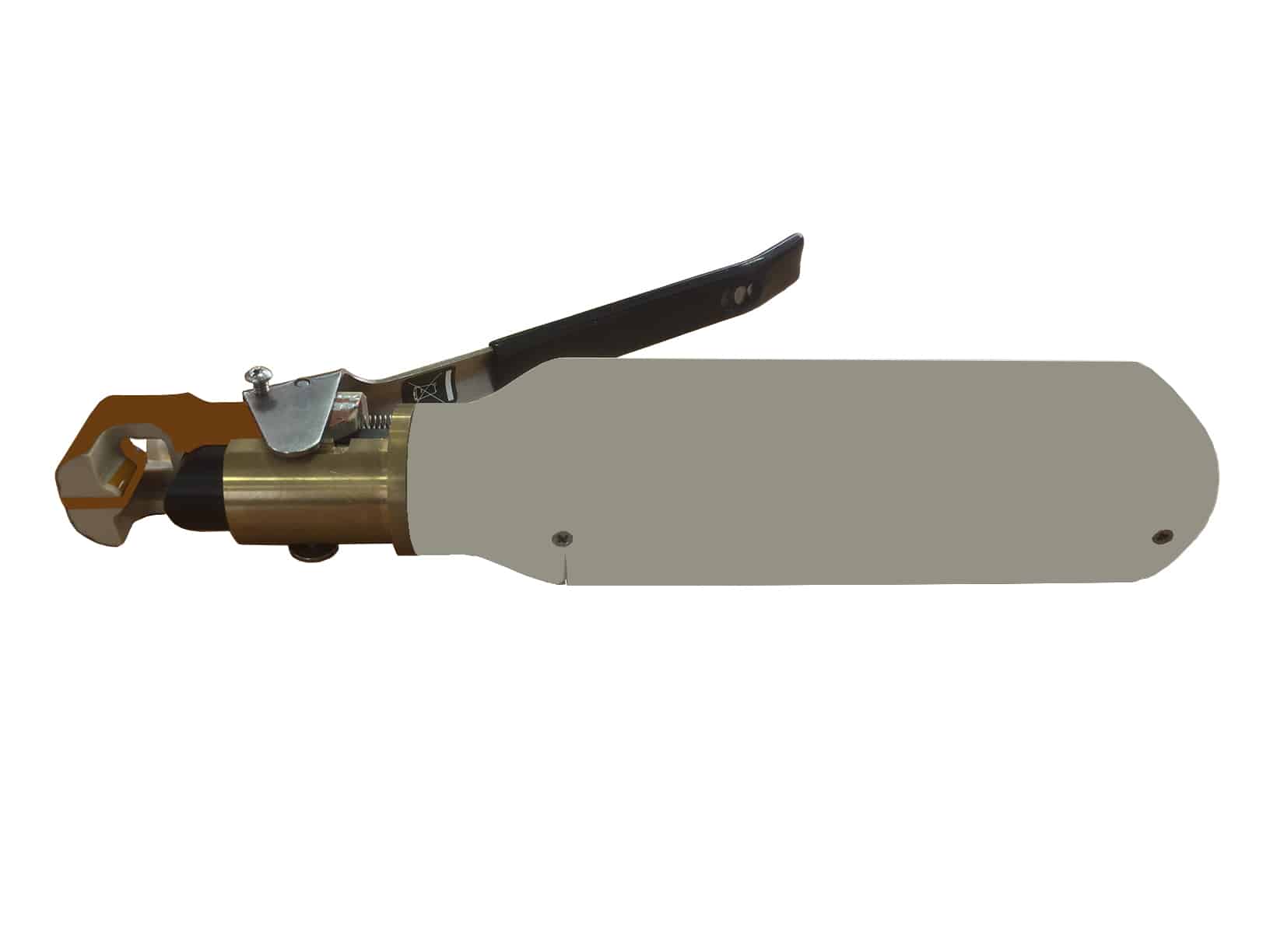

Portable equipment

Light & Cordless

Wearable Devices

Miniaturized Endoscopes

Active Implants

We challenge miniaturization

to help you address unmet medical needs

Electronic miniaturization of medical devices, or the integration of an increasing number of functionalities into thinner and smaller spaces, is a challenge. The use of tiny components in miniaturized devices requires expertise for the design of new and innovative PCB layouts and packaging structures. Also, it calls for new ways of handling and placing components, the ability to achieve ultra-fine pitches, customized test strategies, and innovative manufacturing and automation processes. Valtronic has developed custom integration processes allowing for the highest densities and significant size reductions over conventional technologies.

Customized HDI PCB layouts

The trend for miniaturization implies an increasing demand for smaller, thinner and highly integrated (HDI) PCBs. Innovative medical devices such as highly miniaturized implants require 3D architectures with substrates that can be folded in appropriate areas.

Our engineering team will help you design or improve your PCBs to reach high density interconnects that include all the functionalities requested in a limited space. Our experience includes designs with rigid, flex, and rigid-flex build-ups.

Customized 3D packages

With our expertise in flip chip bonding we design and manufacture components in the form of innovative 3D packages. Several dies can be stacked with ultra-fine pitch solder flip chip and wire bonding. These components that are customized to your needs can then be easily placed on your circuit board.

Ultra-fine pitches

- Flip Chip BGA Package: 150 µm pitch, 100 µm pads and 93 µm ball diameter.

Your benefits

Customized HDI components

From design to manufacturing

Easy to place on your boards

Equipment size reduction

Allowing you to follow the latest trends for wearable and portable devices

Extreme miniaturization

For tiny and reliable active implants and endoscopic devices

Ultra fine pitches

BGA and wire bonding