Getting your medical device to the right place, at the right time, and at the right cost

With our supply chain management processes, we improve the overall effectiveness of your product, from design and development to manufacturing and delivery. From Bill of Material optimization to product end of lifecycle, our teams focus on operational excellence to deliver products of highest quality wherever you need them.

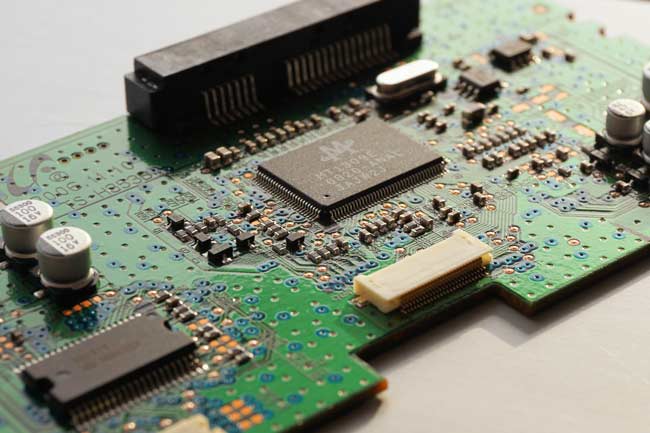

Sourcing already considered at the engineering stage

When designing your device from scratch, or redesigning your product, our engineering teams pays attention from the start at manufacturability. They work in close collaboration with our procurement team to make a thorough BOM forecast and analysis. Their objective is to ensure high-quality manufacturing of your product throughout its lifecycle. This means among others to avoid components which are close to obsolescence and to ensure second source alternatives for critical components.

Operational excellence – For on time and in Full delivery

Through full collaboration between D&D, Manufacturing and Procurement we ensure the continuous supply of all components and parts your product requires. With more than 20 years of international experience in all aspects of a supply chain, our Customer Fuffilment Centers are designed for operational excellence. With continuous analysis and improvement of our supply chain programs. our teams have one objective in mind, which is to deliver your product on time, in full and with continuous cost optimization.

Your benefits at a glance

SCM Throughout Product Lifecycle

Sourcing already considered in the engineering phase

Management of obsolescence and material shortage

On Time & In Full

Highly qualified and experienced Directors of Operations striving for Operational Excellence

Experience with Complex Devices

Handling of large BOMs

> 1000 components

Cost Saving Initiatives

Ongoing supply chain process analysis and improvement